Nestled in the heart of Virginia, the machine shop in Manassas stands as a beacon of innovation and craftsmanship. This facility has become a vital hub for various industries, including aerospace, automotive, and defense, providing essential machining services that cater to the specific needs of its clients. The shop’s strategic location allows it to serve not only local businesses but also national and international clients, making it a key player in the manufacturing landscape.

With a rich history rooted in traditional machining practices, the shop has evolved to embrace modern technologies and methodologies, ensuring that it remains competitive in an ever-changing market. The machine shop in Manassas is characterized by its commitment to quality and precision. It boasts a diverse range of equipment, from CNC (Computer Numerical Control) machines to manual lathes and mills, enabling it to handle a wide array of projects.

This versatility is crucial in meeting the demands of various sectors, where specifications can vary dramatically. The shop’s reputation for reliability and excellence has been built over years of dedicated service, making it a trusted partner for companies seeking high-quality machined components. As industries continue to advance, the machine shop remains at the forefront, adapting to new challenges and opportunities with agility and expertise.

Utilizing Advanced Technology for Precision Machining

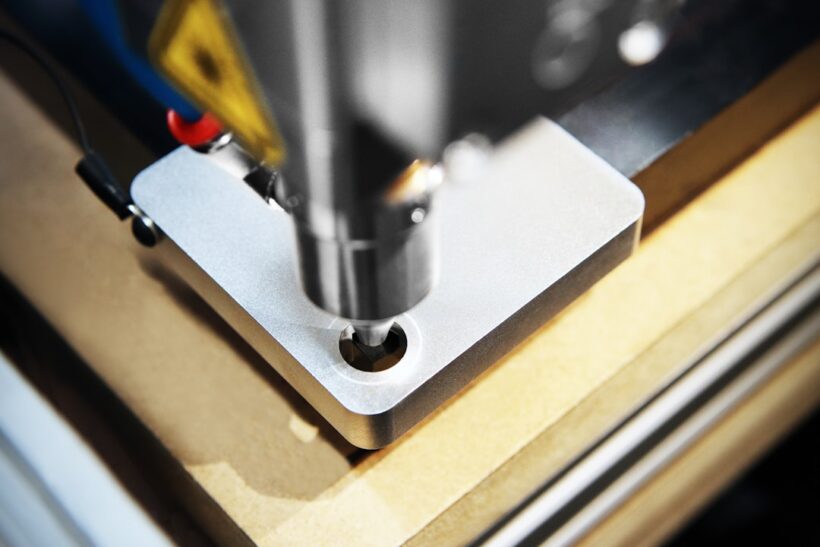

In the realm of precision machining, technology plays a pivotal role in enhancing productivity and accuracy. The machine shop in Manassas has invested significantly in advanced machinery and software that facilitate intricate designs and complex geometries. CNC machines, for instance, are equipped with sophisticated programming capabilities that allow for the automation of machining processes.

This not only reduces human error but also increases efficiency by enabling the production of parts with tight tolerances consistently. The integration of CAD (Computer-Aided Design) software further streamlines the design process, allowing engineers to visualize and modify components before they are manufactured. Moreover, the adoption of additive manufacturing technologies, such as 3D printing, has opened new avenues for the machine shop.

This innovative approach allows for rapid prototyping and the creation of complex shapes that would be challenging or impossible to achieve through traditional machining methods. By leveraging these advanced technologies, the machine shop can respond swiftly to customer demands, producing prototypes in a fraction of the time it would take using conventional techniques. This capability not only enhances customer satisfaction but also positions the shop as a leader in technological advancement within the machining industry.

Implementing Lean Manufacturing Principles for Streamlined Operations

Lean manufacturing principles have become integral to the operations of the machine shop in Manassas, driving efficiency and reducing waste throughout the production process. By focusing on value creation and minimizing non-value-added activities, the shop has been able to optimize its workflow significantly. One of the key strategies employed is the implementation of just-in-time (JIT) inventory management, which ensures that materials are available precisely when needed, thus reducing excess inventory costs and storage space requirements.

Additionally, the machine shop has embraced continuous improvement methodologies such as Kaizen, which encourages all employees to contribute ideas for enhancing processes and eliminating inefficiencies. Regular team meetings are held to discuss potential improvements, fostering a culture of collaboration and innovation. For example, operators may suggest modifications to machine setups that reduce changeover times or identify bottlenecks in production that can be addressed through better scheduling or resource allocation.

This proactive approach not only enhances productivity but also empowers employees by involving them in decision-making processes.

Skilled Workforce and Continuous Training for Optimal Performance

| Metrics | 2018 | 2019 | 2020 |

|---|---|---|---|

| Number of skilled workforce | 500 | 550 | 600 |

| Training hours per employee | 20 | 25 | 30 |

| Employee satisfaction with training | 75% | 80% | 85% |

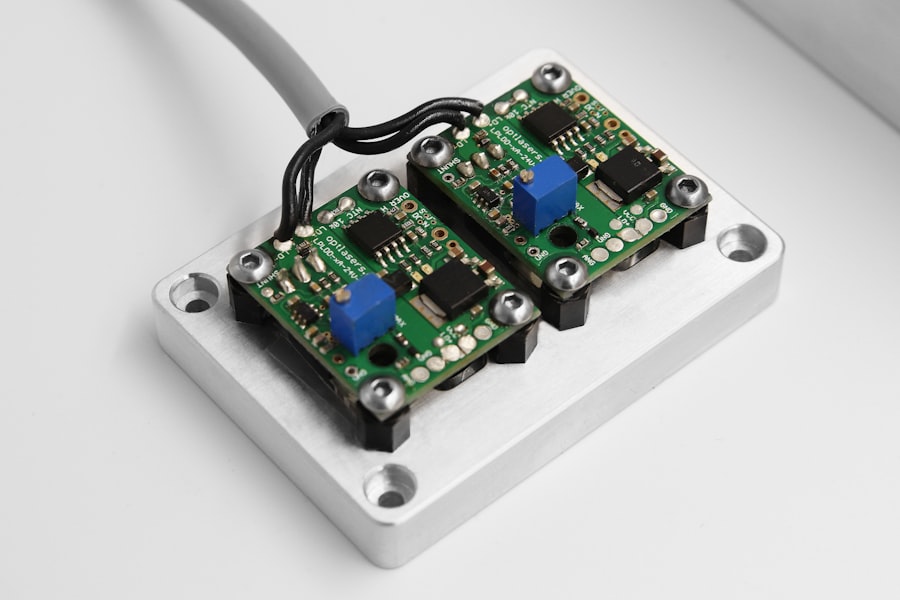

At the core of the machine shop’s success is its highly skilled workforce, which is essential for maintaining high standards of quality and precision. The shop employs machinists with diverse backgrounds and expertise, ensuring that a wide range of skills is available to tackle various projects. However, recognizing that technology and industry standards are constantly evolving, the management places a strong emphasis on continuous training and professional development.

Training programs are tailored to meet the specific needs of employees, covering everything from advanced machining techniques to safety protocols and quality assurance practices. For instance, machinists may participate in workshops focused on mastering new CNC programming languages or learning about the latest advancements in materials science. By investing in their workforce’s education, the machine shop not only enhances individual performance but also fosters a culture of excellence that permeates every aspect of operations.

This commitment to skill development ensures that employees remain at the forefront of industry trends and technological advancements.

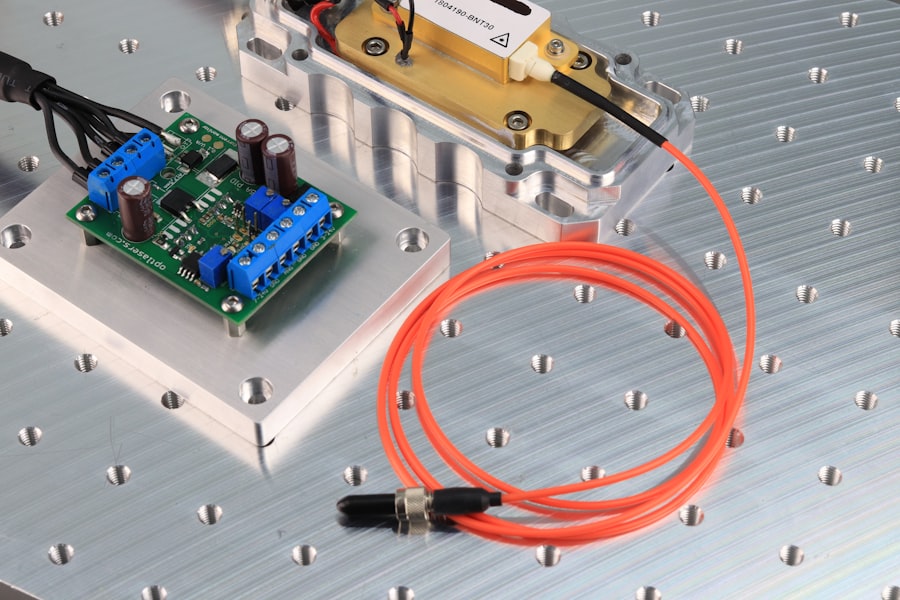

Quality Control and Inspection Processes for Consistent Results

Quality control is a cornerstone of operations at the machine shop in Manassas, where meticulous inspection processes are implemented to guarantee that every component meets stringent specifications. The shop employs a multi-faceted approach to quality assurance, utilizing both automated systems and manual inspections to verify dimensions, tolerances, and surface finishes. Advanced measurement tools such as coordinate measuring machines (CMM) are employed to provide precise data on part geometry, allowing for immediate feedback during production.

In addition to real-time inspections, the machine shop adheres to rigorous quality management systems that align with industry standards such as ISO 9001. Regular audits are conducted to assess compliance with these standards, ensuring that processes remain effective and efficient. Furthermore, feedback loops are established between production teams and quality control personnel to address any issues promptly.

This proactive approach not only minimizes defects but also fosters a culture of accountability where every employee understands their role in maintaining quality throughout the manufacturing process.

Sustainable Practices and Environmental Responsibility in the Machine Shop

As environmental concerns continue to gain prominence across industries, the machine shop in Manassas has taken significant strides toward sustainability and environmental responsibility. Recognizing its role in minimizing ecological impact, the shop has implemented various practices aimed at reducing waste and conserving resources. For instance, efforts have been made to optimize energy consumption by investing in energy-efficient machinery and lighting systems.

These upgrades not only lower operational costs but also contribute to a reduced carbon footprint. Additionally, waste management practices have been refined to promote recycling and proper disposal of materials. Metal shavings and scrap generated during machining processes are collected and sent to recycling facilities rather than being discarded as waste.

The shop also actively seeks out environmentally friendly materials whenever possible, opting for suppliers who prioritize sustainable practices in their operations. By integrating these sustainable practices into its business model, the machine shop not only complies with regulatory requirements but also positions itself as a responsible corporate citizen committed to protecting the environment for future generations. In summary, the machine shop in Manassas exemplifies how traditional craftsmanship can harmoniously coexist with modern technology and sustainable practices.

Through its commitment to precision machining, lean manufacturing principles, skilled workforce development, rigorous quality control measures, and environmental responsibility, it continues to thrive as a leader in the manufacturing sector.